Enzyme Technology: Application and Commercial Production of Enzymes

Introduction

Enzymes are the biocatalysts that are synthesized within the

bodies of living organisms. The enzymes are actually complex proteins and are

responsible for carrying out reactions that are related to life. Enzymes can

catalyse functions even when they are isolated from the cells i.e. in vitro.

Enzymes are basically biodegradable and nontoxic. Certain microorganisms can

produce large amount of enzymes for industrial applications.

|

| Enzyme technology |

Enzyme technology

Enzyme technology consists of production, isolation,

purification, and utilization of enzymes for the welfare of mankind. Enzyme

technology also involves the production of more useful and efficient enzymes

through protein engineering and DNA recombinant technology.

The industry of biotechnology involved the commercial

manufacturing and utilization of enzymes as its major part. The specialized

fields like chemistry, biochemistry, process engineering and microbiology have

major contribution for the growth and development of enzyme technology.

General Considerations of Enzyme Technology:

Generally the techniques used for microbial production of enzyme

are similar to the methods employed for the production of other industrial

products. The main features are briefly described below.

1. Organisms selection

2. Medium formulation

3. Production method

4. Enzyme recovery and purification

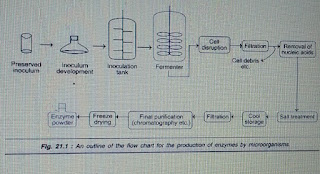

An outline of the flow chart for enzyme manufacture by microorganisms

is depicted in Fig.1.

|

| Fig.1. An outline for production of enzymes by microorganisms |

Organism selection:

The microorganisms which are selected for enzyme production

should be capable of producing maximum quantities of required enzyme in a short

span of time and production of other metabolites should be minimum. After

selection of organism, the next step is strain improvement for optimization of

enzyme production by appropriate method such as UV production or mutagens. The

inoculum can be synthesized from the chosen organism in a liquid medium.

Medium formulation:

The culture medium selected should carry all the nutrient that

are essential for the sufficient growth of microorganism and eventually result

in large quantities of enzyme production. The ingredients used for medium

should have low cost and nutritionally intact. The frequently employed

substrates for the medium are molasses, corn steep liquor, starch hydrolysate,

whey, yeast extract and soy bean meal. Some pulses such as peanut and some

cereals such as wheat have also been employed. For maximum microbial growth and

good enzyme production, the pH of the medium should be optimum.

Production process:

Industrial manufacturing of enzymes is preferably accomplished by

submerged liquid conditions and to a smaller extent by solid-substrate

fermentation.The submerged culture technique gives more yield and contain

lesser chances of infection. Therefore this is the mostly used method. However,

solid substrate fermentation has its own historical importance and still in use

for the manufacture of fungal enzyme such as celluloses, pectinases, amylases

and proteases.

The batch or continuous sterilization techniques can be employed

for sterilization of medium. The start of the fermentation involves the

inoculation of the medium. The growth conditions such as pH, oxygen supply,

temperature and nutrient addition are regulated at optimal level. Anti-foam

agents can be used to minimize froth formation.

The fermentation process which is commonly employed for enzyme

production is batch fermentation and continuous process is employed to a lesser

extent. The fermentation process should contain sterile bio-reactor throughout

the process. The fermentation process has variable duration around 2-7 days in

majority of production processes. Various other metabolites are also produced

in addition to desired enzyme production. Therefore recovery and purification

of enzyme is necessary.

Recovery and purification of enzymes:

The desired enzyme to be manufactured may be present within the

cell that is intracellular enzyme or may be excreted inside the culture medium

that is extracellular enzyme. It depends on the commercial requirement that the

enzyme may be highly purified or may be crude. Furthermore, it may be in the

liquid or solid form. The degree of purity desired and the nature of enzyme

decides the steps involved in the recovery and purification process.

Generally, the recovery of an extracellular enzyme from the

broth is simpler in comparison to an intracellular enzyme. Special techniques

are required for cell disruption in order to release intracellular enzyme.

Several physical means such as high pressure, sonication and glass beads can be

employed to break down the microbial cell. Lysozyme enzyme can be used to break

the bacterial cell. The enzyme β-glucanase is used for yeasts. But the

enzymatic methods are expensive.

The recovery and purification steps are same for both

extracellular and intracellular enzymes after the disruption and release of

intracellular enzyme. The main consideration is to reduce the loss of desired

enzyme activity.

Removal of cell debris:

Cell debris can be removed by centrifugation or filtration.

Removal of nucleic acids:

There may be interference of the nucleic acids during the

recovery and purification of enzymes. Their interference can be removed by

precipitation and by the addition of poly-cations such as streptomycin,

polyamines and polyethyleneimine.

Enzyme precipitation:

Enzymes can be precipitated by utilizing organic solvents such

as ethanol, isopropanol and acetone and by using ammonium salts such as

ammonium sulfate. Precipitation has advantage since the precipitated enzyme can

be dissolved in a minimal volume in order to concentrate the enzyme.

Liquid-liquid partition:

Further concentration of desired enzyme can be accomplished by

liquid-liquid extraction utilizing polyamine or polyethylene glycol.

Separation by chromatography:

The separation and purification of enzymes can be carried out by

various chromatographic techniques. These include size exclusion, hydrophobic

interaction, ion exchange, dye ligand and affinity chromatography. Among these

methods, ion exchange chromatography is the most frequently employed

chromatography for enzyme purification.

Drying and packing:

Drying can be used to obtain the concentrated form of enzyme.

Film evaporators or steam dryers can be used for this purpose. After drying,

the next step is packing and ultimately enzyme can be marketed. Ammonium

sulphate suspensions can be used to achieve the stability of certain enzymes.

All the enzymes which are used in medical treatments or food

must have purity of high grade and must fulfil the required specifications by

regulatory bodies. Toxic material and harmful microorganism must be totally

absent in these enzymes and enzymes should not cause allergic reactions.

General Considerations for Regulation

of Microbial Enzyme Production:

A maximal yield of microbial enzymes can be obtained by optimising

the fermentation conditions such as nutrients, O2, pH, temperature

etc.. For this aspect, a complete understanding of the genetic regulation of

enzyme production is needed. Some of the general features of microbial enzyme regulation

are briefly discussed below

Induction:

Various enzymes are inducible i.e. they are prepared only by

using inducers. These inducers may be the substrate such as sucrose,

galactosides, starch or intermediate such as fatty acid, xylobiose , phenyl

acetate. Some enzymes and their inducers are given in Table 1.1.

Enzyme

|

Inducer

|

Invertase

|

Sucrose

|

Amylase

|

Starch

|

Lipase

|

Fatty acid

|

ẞ-Galactosidase

|

Galactosides

|

Penicillin G

amidase

|

Phenylacetate

|

Xylanase

|

Xylobiose

|

Table.1. Examples of

inducible enzymes with the inducers

The inducer compounds are costly and their processing such as

sterilization and addition at specific time is fairly difficult. Recently,

effors are being made to produce mutants of microorganisms to eliminate the

dependency of inducers.

Feedback repression:

Enzyme synthesis is significantly influenced by the feedback

regulation of the end product. This happens due the accumulation of large

quantities of the end product. The production of feedback regulated enzymes on

large scale is quite difficult. To overcome this problem, mutants have been developed

that lack feedback repression.

Nutrient repression:

The native metabolism of microorganism is devised in such a way

to avoid the production of unnecessary enzymes. The production of undesired

enzymes can be inhibited by nutrient repression. The nutrients may be nitrogen,

carbon, sulphate or phosphate fertilizers in the growth medium. Nutrient

repression must be overcome to produce enzymes on large scale.

The classical example of nutrient repression is glucose

repression. The synthesis of enzymes that are needed for the metabolism of rest

of the compounds is inhibited by the presence of glucose. By feeding

carbohydrates to the medium, the glucose repression can be overcome. Mutants

have been made to resist the catabolite repression by glucose. For various

microorganisms, other carbon sources such as lactate, succinate, pyruvate and

citrate are also used as catabolite repressors.

Microorganisms have also shown nitrogen source repression.

Ammonium ions or amino acids may be responsible for this. Ammonium salts are

commonly used as a source of nitrogen repression because these are inexpensive.

Nitrogen repression can be overcome by developing mutants.

Microbial Enzyme Production by Genetic Engineering:

The functional products of genes are enzymes. Therefore,

improved productions of enzymes can be developed through genetic engineering.

During the past 15 years, the microbial production of commercial enzymes have

been increased considerably through advancement in genetic engineering. Desired

enzyme genes can be now transferred from one organism to the other. The relevant genes of commercial enzymes

having potential uses can be now cloned and insertion can be carried out into a

suitable production house.

Cloning strategies:

Cloning strategies involves developing the cDNA library for the

mRNA and creating the oligonucleotides probes for the selected enzymes. The

specific cDNA clones can be identified by hybridization with oligonucleotide

probes.

|

| Fig.2. Cloning |

For the production of desired enzyme, the next step is

transformation of industrially significant host organism such as Aspergillus

oryzae. High quality industrial enzymes can be prepared by using this approach.

A couple of enzymes prepared by using cloning strategies are discussed below:

1. Fat strains in the fabrics can be removed effectively by the

enzyme lipolase present in fungus Humicola lanuinosa. However due to the low

level production, industrial synthesis of lipolase by this organism is not

possible. So the genes responsible for lipolase production have been isolated,

cloned and inserted into the Aspergillus oryzae.

Thus, industrial production of this enzyme was successfully

obtained. Lipolase shows stability and resists degradation by proteases that

are frequently used in detergents. Therefore lipolase is a strong candidate for

utilizing in fabric washing due to these properties.

2. Rennet (chymosin) is commonly used enzyme in making cheese.

It is mainly produced by the stomach of young calves. As a result, its supply

is short. This has been solved by cloning the genes of chymosin for its

industrial production.

Modification of industrial enzymes by protein engineering:

Protein engineering and site directed mutagenesis can be used to

alter the structure of enzymes. The changes in the enzymes have been carried to

achieve increased stability, resistance to oxidation, improved catalytic

function, high tolerance to organic solvents and alkali and changed substrate

preferences.

Site directed mutagenesis can be employed to change the selected

amino acids at specific positions for the production of enzymes with desired

properties. Phospholipase A2 that resist high concentration of acid

have been structurally modified by genetic engineering. The modified enzymes

are more efficient for using as food emulsifier. Industrial production of

enzymes with desired properties have been achieved by genetic engineering in a

cost effective manner.

No comments:

Post a Comment